Soft capsules are made with an aqueous gelatin solution containing a plasticizer, such as glycerol or sorbitol. Two formed strips of film are run between suitable negative molds, and as the rolling female molds approach, the filling is injected and the capsule halves are sealed together. Gelatin is also used for microencapsulation of drugs, ie the active drug is encapsulated in a microcapsule or sachet and then processed as a powder. The earliest microencapsulated drugs (capsules) were fish oil and oily vitamins encapsulated in a gelatin capsule prepared by an emulsification process.

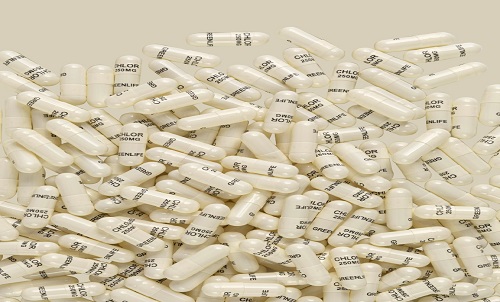

Customed Full ribbon letter 00# 00#el 0# 0#el 1# 1#el 2# 3# 4# 5# Gelatin hollow capsule

中文简体

中文简体 English

English